Introduction

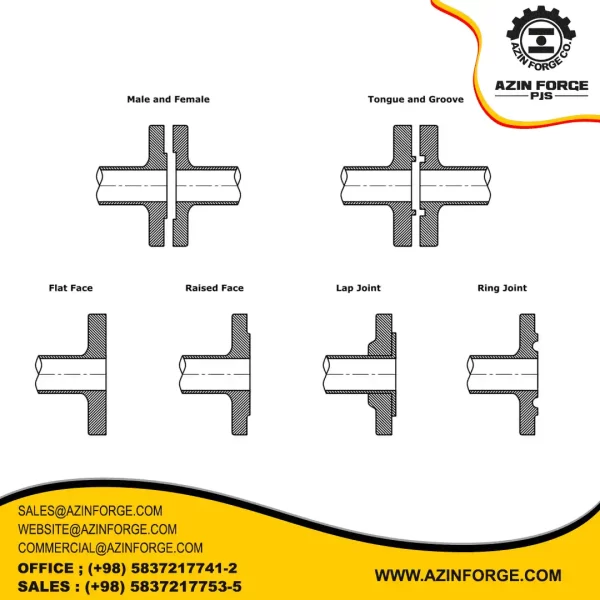

Flanges are divided into several different types in terms of disc surface, such as Ring Type Joint (RTJ) Flange, Raised Face (RF) Flange, Flat Face (FF) Flange, male and female (M&F) Flange and… In this article, we are going to introduce flanges and types of face flanges to you and examine each of them separately. We will also examine their features and advantages and disadvantages.

What is a Flange?

A flange is a connecting part that is used to connect two pieces of pipe or industrial equipment to each other. Flanges are usually made of metals such as steel, aluminum, copper, or brass and are bolted together. Flanges are used in oil, gas, petrochemical, water and sewage industries and other industries.

Types of face flanges

Flanges are divided into the following according to the surface of the disk or the so-called face flange:

1- Ring Type Joint (RTJ) Flange

2- Raised Face (RF) Flange

3- Flat Face (FF) Flange

4- Lap Joint Flange

5- Tongue & Groove (T&G) Flange

Male and Female (M&F) Flange

Ring Type joint (RTJ) Flange

Ring Type Joint (RTJ) Flange is a types of face flanges that is used as a connector in high pressure and temperature. These types of flanges are used for connections that require strong compression. Ring Type Joint Face Flange is commonly used in piping systems of oil, gas, chemical and other industries that deal with high pressure and temperature.

Feature of Ring Type Joint (RTJ) Flange

1- It has a special cutting surface that is compatible with the cutting surface of pipes and industrial equipment.

2- It has a ring joint (ring connection) that can perform well at high pressures and high temperatures due to its special welding.

3- It has high resistance to corrosion, scratches and wear.

4- It can work well against high pressures and temperatures including steam pressure, gas pressure and liquid pressure.

Advantages and disadvantages of Ring Type Joint (RTJ) Flange

Advantages:

1- High resistance: flange with ring joint surface has high resistance against pressure and temperature. So it is very suitable for this situation.

2- Tight connection: This type of flange provides a tight connection and prevents leakage due to its special design.

3- Indentation: It has a circular indentation on the inner surface of the flange, which is secured and sealed by ring gaskets.

Disadvantages:

1- Complexity of installation: This type of flange may be complicated due to the ring joint and the need for special welding, its installation and connection.

2- High cost: Flange with ring joint surface may be more expensive than normal flanges due to high resistance and special design.

3- The need for high precision: To install and use a flange with a ring joint surface, you need high precision and accuracy in welding and installation operations.

Raised Face (FF) Flange

Raised Face (RF) Flange is a types of face flanges that has a raised surface around the hole for sealing. This flange is used to connect pipes or equipment to each other and they are connected through bolts. The raised surface of this flange makes the connection between the two parts stronger and prevents leakage. This type of flange is suitable for use in medium and high pressures and temperatures.

Feature of Raised Face (RF) Flange

1. Raised surface: A flange that has a circular protrusion around the central hole. This Raised Face (RF) causes better pressure to be created by the raised surface when connecting two flanges together, which somehow prevents leakage.

2. Tight connection: The raised surface of the flange creates a tight connection between the two flanges, which prevents leakage and withstands pressure well.

3. Wide use: The flange with raised surface is used in various industries including oil and gas, petrochemical, power plants and chemical industries due to its strong connection capability and suitable for high pressure and high temperature connections.

Advantages and Disadvantages of Raised Face (RF) Flanges

Advantages:

1. Tight connection: The flange with a raised surface due to its circular protrusion creates a tight connection between the two flanges, which prevents leakage.

2. Flexibility: This type of flange can be connected to different types of pipes and equipment and therefore has high flexibility.

3. Pressure resistance: The flange with raised surface has high pressure and temperature resistance and is suitable for connections with harsh conditions and high pressure environments.

Disadvantages:

1. High cost: Compared to some other flanges, raised face (RF) Flange is more expensive and may not be economical for some projects.

2. The need for high precision: To install and use a raised face Flange, you need high precision and accuracy in performing installation and welding operations, which may be time-consuming.

3. Complexity of installation: The installation and connection of a flange with a raised face may be complex and requires experience and expertise due to the need for special welding and compliance with strict standards.

In general,this flange has its advantages and disadvantages and should be compared with the specific conditions and needs of the project in order to make a suitable decision to use it.

Flat Face (FF) Flange

Flat Face (FF) Flange is a types of face flanges whose inner surface is smooth without edges or cutting rails. This type of flange is used to connect pipes or equipment together and is usually suitable for lower pressures and normal temperatures. Since its surface is smooth, it is necessary to use a gasket on the entire surface of the flange to prevent leakage.

Feature of Flat Face (FF) Flange

1. Smooth surface: this piece has a smooth surface without any special protrusions or indentations. This feature makes the connections with this type of flange completely smooth and integrated.

2. Suitable for low pressures: The flat face flange is well suited for low-pressure connections. This type of flange may not be able to prevent leakage well at high-pressures due to its smooth surface and no protrusions.

3. Use in simple conditions: The flange with a smooth surface is suitable for use in simple conditions and general applications due to its simplicity and the absence of special protrusions and procedures.

4. Easy installation and replacement: This type of flange is easy to install and replace due to the simplicity of its structure and the absence of protrusions, and does not require high precision in performing this operation.

AzinForge has a 4000 ton hydraulic press, a 5-meter rinf rolling, counterblow hammer and a carousel, with the help of these machines, quality forged parts such as flanges, pipes, rims, light and heavy car parts, shipbuilding, rail, etc. produces

Advantages and Disadvantages of Flat Face Flange (FF)

Advantages:

1. Easy installation: The flange with a smooth surface is easy to install due to its simple structure and the absence of protrusions, and does not require special equipment and processes.

2. Reasonable price: This type of flange is less expensive due to the simplicity of the structure and the use of cheaper materials, and it is suitable for projects with a limited budget.

3. Suitable for simple conditions: the flange with smooth surface is suitable for use in simple conditions and general applications and does not require high pressures or special conditions.

Disadvantages:

1. The need for fine adjustment: to prevent leakage, the flange with a smooth surface needs to be fine-tuned and use appropriate methods to compress and prevent leakage.

2. Unsuitable for high-pressures: This type of flange may not be able to prevent leakage well at high pressures due to its simple structure and lack of protrusions and is not suitable.

3. Limitations in use: Due to its limitations, the flange with a flat surface is not suitable for some connections and special conditions, and requires the use of other flanges.

In general, the flat face flange is suitable for use in simple conditions and general applications due to the simplicity of the structure and reasonable price. But in conditions with high-pressures and the need for higher performance, it may not be suitable.

Lap Joint (LJ) Flange

The lap joint Flange is consists of two parts. It is the lap joint ring and the stub end, that the end stub is placed inside the lap joint and is welded to the pipe. This type of flange is used in many industries due to its simplicity and ease of installation. Among the applications of this flange, we can mention the connection of pipes, connections of industrial equipment, connections of air conditioning and heating systems.

Contact our specialists in the sales unit for advice, order and purchase of your desired product and inquire about the price.

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Feature of lap joint (LJ) flange

1. Structure: The lap joint flange has two main parts, including the stub end and the lap joint ring. The lap joint is usually made of carbon steel or stainless steel, and the stub end is usually made of stainless steel.

2. Easy installation: One of the important features of lap joint flange is its easy installation. This type of flange is easy to install and replace due to the stub end that is separated from the lap joint.

3. Movable connection: One of the unique features of lap joint flange is its movable connection. This means that the stub end can move easily into the lap joint, allowing the pipes to be easily adjusted.

4. Adjustability: Due to its movable connection, the lap joint flange provides the ability to adjust and change the direction of the pipes.

5. Use in high temperature and pressure: Due to its special structure, this type of flange can be used in conditions with high-pressure and different temperatures.

6. Separability: Another feature of the lap joint flange is its separability, which allows the pipes to be easily separated without having to remove the flanges.

Advantages and disadvantages of lap joint (LJ) flange

Advantages:

1. Easy installation: Lap joint flange provides easy installation of connections due to its detachable stub end.

2. Adjustment and change of direction: This type of flange provides the possibility of adjusting and changing the direction of pipes due to the movable connection of the end of the stub.

3. high temperature and pressure: this flange can be used in conditions with high-pressure and different temperatures due to its special structure.

Disadvantages:

1. Cost: A lap joint flange may be more expensive than some other flanges.

2. Need more space: Installing the lap joint flange requires more space than some other flanges.

3. Limitation in pressure: In some cases, the lap joint flange may have limitations in high-pressures.

In general, the lap joint flange is suitable for use in joints that require adjustment and change of direction due to its features of ease of installation, movable connection, adjustability and disconnectability. But it should be noted that in some situations, it may have limitations.

Tongue and Groove (T&G) Flange

Tongue & Groove flange is a types of face flanges that is used to connect two pieces of pipe or industrial equipment. This type of flange has a tongue and a groove that are mutually placed with each other. A tongue is a raised edge and a groove is an indented edge that overlaps.

Feature of Tongue and Groove (T&G) flange

1. Strong connection: The tongue and groove design makes the connection between two flange pieces very strong and stable.

2. Resistance to pressure: The flange with tongue and groove surface has a high resistance to pressure and vibrations due to its special design.

3. Protection against leakage: This flange has a high resistance against leakage due to the connection of the tongue and groove surface.

4. Ease of installation: the flange with tongue and groove surface is easy to install due to its special design.

5. temperature and pressure conditions: this type of flange can be used in different temperature and pressure conditions.

Advantages and disadvantages of Tongue and Groove (T&G) flange

Advantages:

1. Tight connection: The flange with tongue and groove surface provides a tight connection between two flange pieces due to its special design.

2. Resistance to pressure: This type of flange has a high resistance to pressure and vibrations due to its special design.

3. Protection against leakage: The connection of tongue and groove surface makes the flange have high resistance against leakage.

Disadvantages:

1. accuracy in installation: to install a flange with a tongue and groove surface, very high accuracy is needed in the compression and placement of parts.

2. Limitations on replacement: If it is necessary to replace a part of the connection, the flange with tongue and groove surface may require the replacement of all parts, which can be time-consuming and expensive.

3. Limitation in flexibility: this type of flange may not be suitable in cases that require flexibility and deformation.

In general, the tongue and groove flange is suitable for certain applications, including connections that require high resistance to pressure and leakage, due to their advantages and disadvantages. But it should be considered that in some cases, there may be certain restrictions.

Male and Female (M&F) Flange

Male and Female (M&F) flange has a male surface and a female surface, which is used to connect two flange pieces together. This type of flange is commonly used in connecting pipes and industrial equipment.

Feature of Male and Female (M&F) flange

1. Tight connection: The male and female (M&F) flange has a special design that provides a tight connection between the two flange pieces. Becuase, this feature is very important in cases where a tight and leak-free connection is needed.

3. Pressure resistance: This flange is usually used for connections that require high pressure resistance.

4. Leakage resistance: The male and female (M&F) flange can well prevent leakage and provide a tight connection.

5. environmental conditions: this type of flange can be used in different temperature and pressure conditions.

6. Easy installation and commissioning: The male and female (M&F) flange is easy to install and commissioning due to its convenient design.

Advantages and disadvantages of Male and Female (M&F) flange

Advantages:

1. Tight connection: The male & Female flanfe has a special design that provides a tight connection between the two flange pieces. This feature is very important in cases where a tight and leak-free connection is required.

2. Flexibility: Male and Female (M&F) flange has high flexibility due to its design.

3. Pressure resistance: This type of flange is usually used for connections that require high pressure resistance.

4. Leakage resistance: The male & female flange can well prevent leakage and provide a tight connection.

5. environmental: this type of flange can be used in different temperature and pressure conditions.

6. Easy installation: M&F flange is easy to install and operate due to its convenient design.

Disadvantages:

1. Restrictions on replacement: If a part of the connection needs to be replaced, the M&F flange may require the replacement of all parts, which can be time-consuming and expensive.

2. High cost: Installing and using M&F flanges may be more expensive than other methods.

Due to these advantages and disadvantages, flanges with male and female faces are a good choice for connections that require a tight connection, resistance to pressure and leakage, and flexibility. But it should be kept in mind that in some cases, there may be certain restrictions.

Sales department (Central):

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Sales department (Tehran):

| Phone number | |

|---|---|

| +9821-44443106 | commercial@azinforge.com |

Sales department (Mashhad):

| Phone number | |

|---|---|

| +9851-37597237 | commercial2@azinforge.com |

Follow AzinForge on LinkedIn and get access to our latest developments and projects in the field of forging and industrial design. Do not miss this opportunity and connect with us on this social network.